3D Printed Microfish Used for Detoxification

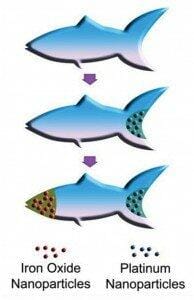

Functionalizing the microfish. Platinum nanoparticles are loaded into the tail for propulsion via reaction with hydrogen peroxide. Next, iron oxide nanoparticles are loaded into the head for magnetic control. Image credit: W. Zhu and J. Li, UC San Diego Jacobs School of Engineering.

Functionalizing the microfish. Platinum nanoparticles are loaded into the tail for propulsion via reaction with hydrogen peroxide. Next, iron oxide nanoparticles are loaded into the head for magnetic control. Image credit: W. Zhu and J. Li, UC San Diego Jacobs School of Engineering.Nanoengineers from the University of California, San Diego have developed fish-shaped microrobots that swim in liquid, are chemically powered by hydrogen peroxide and magnetically controlled. The study, published in the journal Advanced Materials, is a proof of concept for future designs with functionalities as detoxification, sensing and directed drug delivery.

Previously fabricated microrobots have locomotion mechanisms, like engines or microrockets, and simple designs — such as spherical or cylindrical structures. Moreover, they are made of homogeneous inorganic materials. All these characteristics make them incapable of performing sophisticated tasks.

The new microrobots are 120 microns long and 30 microns thick, have platinum nanoparticles in the tails, which react with hydrogen peroxide to propel the microfish forward, and magnetic iron oxide nanoparticles in the heads, which allowed them to be steered with magnets. The innovative design allows integrating many functions in the robots for varied applications. The research team carried out a proof of concept experiment. They incorporated toxin-neutralizing polydiacetylene (PDA) nanoparticles in the microfish. When PDA binds the toxin, it becomes fluorescent and emits red light. The team was able to monitor the detoxification ability of the microfish by the intensity of their red glow. The microfish swimming ability enhanced the detoxification.

New 3D printing technology: μCOP

Chen’s lab has developed a 3D printing technology, called microscale continuous optical printing (μCOP), with high speed, scalability, precision and flexibility. Microrobots imitating other life forms or any shape can be designed. The key feature of μCOP is the digital micromirror array device (DMD) chip, which contains approximately two million micromirrors. Each micromirror is individually controlled to project UV light in the desired pattern (in this case, a fish shape) onto a photosensitive material, which solidifies upon exposure to UV light. The microfish are built using the photosensitive material and are constructed one layer at a time, allowing each set of functional nanoparticles to be “printed” into specific parts of the fish bodies.

Source: UC San Diego