A Hybrid Polymer With Removable Compartments

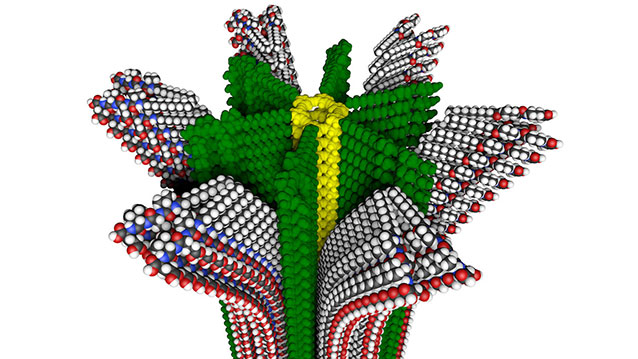

Hybrid polymer with removable supramolecular compartments. Credit: Mark E. Seniw, Northwestern University.

A new kind of hybrid polymer could be used for self-repairing materials, drug delivery and artificial muscles. The polymer, developed by researchers at Northwestern University, features removable parts that can be regenerated. The study has been published in the journal Science.

Our bodies use polymers to sustain cellular structures. For example, the cytoskeleton is made of fibers that consist of monomers assembled by supramolecular interactions like hydrogen bonds. Artificial polymers appeared in two waves: first, covalent polymers; later, noncovalent supramolecular polymers. The major difference between them is the type of link between monomers. Now, the team led by Professor Samuel Stupp has designed the third wave of polymers, assembled by a mix of covalent and supramolecular bonds. The combination of strong and weak bonds allows to design polymers with different properties and compartments.

A polymer with a rigid center and a soft exterior

The new polymer has a covalent, rigid core with a star-shaped cross section. Between the protruding arms, soft, non-covalent polymers can be fitted. These parts are removable and can be chemically regenerated; they could dinamically respond to stimuli and be delivered to the environment, mimicking natural molecular processes. Apart from drug delivery, the soft compartments could be used to generate artificial muscles, energy sources or self-repair structures.

The hybrid polymer could lead to new materials that assemble and disassemble themselves, with innovative functions.

Source: Northwestern