Plastics made of methane threaten oil industry

Plastics are a multibillionaire industry dependent on oil, but this can change soon. Newlight Technologies takes methane emissions and turn them into AirCarbon™ thermoplastic. The innovative carbon capture technology poses a serious threat to the oil industry and can help reduce fossil fuel extraction and gas emission.

In 2003, Princeton undergraduate Mark Herrema read an article about methane emissions from cows. The strategies to minimize methane impact as a greenhouse gas where either taxing it or burying it underground. Herrema thought it would be much better to use it as a resource: transform pollution into plastic. Trapping methane is much more convenient that capturing carbon dioxide due to methane’s higher heat-trapping potential (20 fold) and superior thermodynamics. That same year, Herrema founded Newlight Technologies and started working on designing a biocatalyst that could convert methane to plastic.

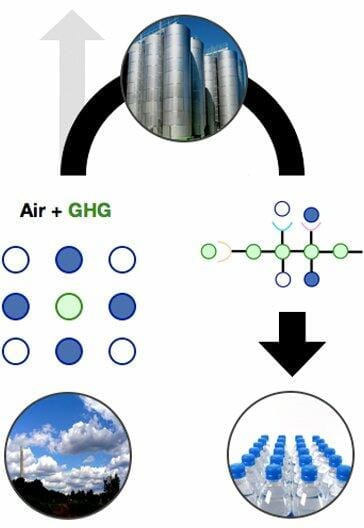

The Newlight GHG-to-Plastic™ Process

Concentrated methane that would otherwise be emitted to the atmosphere is captured from landfills, farms and energy facilities and directed to a conversion reactor. In the reactor, methane is combined with air and Newlight’s biocatalyst, which pulls oxygen out of air and carbon and hydrogen out of methane. Oxygen, carbon and hydrogen polymerize to form the AirCarbon™ thermopolymer. Synthesized plastic is removed from the reactor and transformed in pellets, which can be melted and given any shape.

20-Year Contract for 19 Billion Pounds of AirCarbon PHA

Newlight’s 9X biocatalyst has a yield an order of magnitude higher than previous greenhouse gas-to-polymer biocatalysts. This enables AirCarbon to beat oil-based plastics on price. Now, thanks to a recent agreement with Vinmar, the company operates at a massive commercial scale. Vinmar is a global marketing, distribution and project development company that brings value to the world’s leading producers and users of petrochemical products through tailored business solutions. According to the 20-year contract, Vinmar will buy 19 billion pounds (8.5 billion kg approx.) of AirCarbon polyhydroxyalkanoate (PHA), the compound used to build the biodegradable plastics.

The company has developed the world’s first carbon-negative product made with AirCarbon, the AirCarbon chair, and plan on producing many other carbon-negative products like cars, electronics or apparel.

Source: Newlight Technologies