Riboflavin Based 3D Printing to Produce Compatible Medical Implants

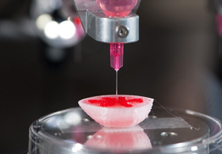

A team of researchers from the University of North Carolina have given the phrase “Vitamins are good for you” a completely new meaning by 3D printing medical implants using vitamin B2, also known as riboflavin. According to the research, the implants made of vitamin B2 are more compatible with human body than its other counterparts.

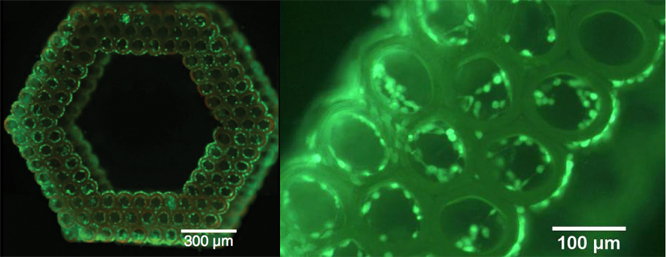

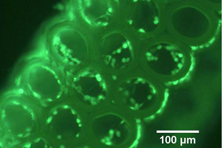

In 3D printing, light sensitive photoinitiators are used to create a 3D printed object. The photoinitiator used in this two photon polymerization process turns a liquid polymer into solid when laser light is focused upon it, and the rest of the liquid not exposed to the focal point of laser can be washed away leaving behind only the solid structure. This method can be used to print biocompatible scaffolds used to grow custom body parts using tissue engineering and also to print micro-needles that can be used for drug delivery applications. Vitamin B2/riboflavin is light sensitive and also non toxic. In this study, the implants printed using a mixture of riboflavin and triethanolamine as a photoinitiator is found to produce scaffolds that are much more biocompatible than those printed using other conventional light sensitive mixtures like Irgacure 369 and Irgacure 2959. Further information about this study is published in the journal Regenerative Medicine.